Service profile

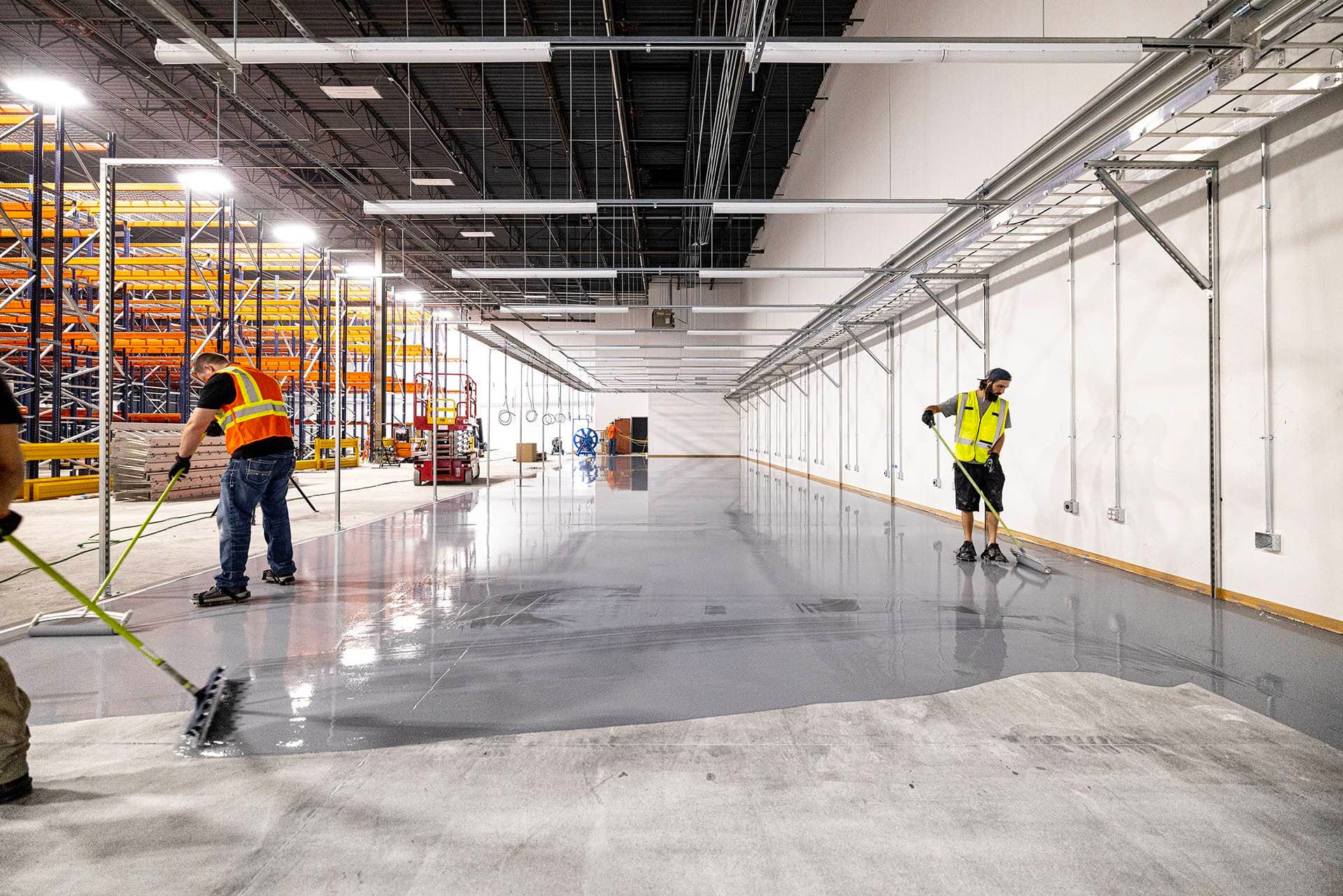

Industrial Warehouse Slabs

Heavy-duty warehouse slabs with curling control, joint planning, and load-bearing reinforcement for automated fulfillment.

- Mobilization

- 5-7 days

- QA reporting

- Daily field logs

- Packages delivered

- 400+

- Crew coverage

- Irving & Metroplex

- Self-performed

- Core scope crews

- Average variance

- <1% schedule

About Industrial Warehouse Slabs

Industrial warehouse slabs in North Texas must handle the demands of modern logistics—heavy racking loads, constant forklift traffic, and the precision required for automated systems. As the DFW Metroplex has become a major distribution hub, the requirements for warehouse floors have grown increasingly sophisticated.

We work directly with developers, property owners, and facility operators to engineer warehouse slabs that will perform for the life of the building. This means understanding your specific operations—racking configurations, forklift types, and future flexibility requirements—not just following generic specifications.

The concrete floor is the largest single element in most warehouse buildings, and it's often the most underappreciated. A floor that seems adequate at turnover can develop problems within years if not properly designed and constructed for actual operating conditions. We've seen too many facilities struggle with floor issues that could have been prevented.

Our crews pour industrial warehouse slabs throughout the DFW logistics corridor—from the massive fulfillment centers along I-35 to the specialized manufacturing floors in Grand Prairie's industrial parks. Each project benefits from our understanding of how these floors actually get used.

What's Included

- Subgrade preparation and compaction verification

- Vapor barrier installation

- Reinforcement installation (rebar or fiber)

- Laser screed concrete placement

- Joint sawing with optimized layout

- Floor flatness surveying and documentation

- Densifier and sealer application

- Dock and equipment pad integration

What this scope delivers

As your general contractor, we engineer, schedule, and execute industrial warehouse slabs packages across Irving, TXfor commercial and industrial projects. Property owners and developers get direct accountability, transparent pricing, and professional project management.

Design-assist alignment

We plug into preconstruction early, reviewing drawings for embed coordination, lift plans, and pour sequencing so industrial warehouse slabs aligns with the broader build.

Crewed for Metroplex speed

Dedicated industrial concrete crews staged across the Metroplex shorten mobilization windows and keep manpower consistent through multi-phase scopes.

Transparent field reporting

Daily warehouse floor slabs updates, photo logs, and testing summaries document every milestone for owner reps and construction managers.

QA/QC baked into pours

Laser layout, third-party testing, and post-pour walks confirm distribution center concrete requirements before downstream trades mobilize.

Commercial & Industrial Applications

Typical applications

Execution framework

How we keep the scope on schedule

- 01

Scope coordination

We align drawings, RFIs, and finish standards with your team to confirm sequencing, logistics, and tolerances before industrial warehouse slabs mobilizes.

- 02

Site logistics & safety

Detailed logistics maps, crane placement, and safety planning keep crews productive and compliant throughout industrial warehouse slabs execution in Irving.

- 03

Field execution

Self-performed crews manage layout, formwork, placement, and finishing with superintendent oversight and real-time reporting.

- 04

Close-out & turnover

Punch walks, testing reports, and as-built documentation verify performance before handing off to downstream trades.

Quality and safety controls

Certified crews & audits

Weekly safety stand-downs, JHAs, and third-party inspections keep our industrial warehouse slabs teams compliant on every Irving, TX jobsite.

Testing & documentation

We coordinate break tests, flatness readings, and special inspections with labs to maintain traceable records for owners and industrial concretes.

Communication rhythm

Look-ahead schedules, coordination huddles, and daily reports ensure no surprises for the GC or owner reps.

Need project-specific QA/QC documentation, submittals, or safety plans? We assemble packages tailored to your owner and AHJ requirements before mobilization.

Measured outcomes

Results owners notice

Every industrial warehouse slabs package is tracked against schedule, QA benchmarks, and owner punch lists so you can move to the next trade with confidence.

- Schedule reliability

- 99% milestones met

- Owner punch items

- <2 per project

- Testing compliance

- 100% logs filed

- Crew retention

- 5+ year leads

Tracked through weekly look-aheads and daily updates to keep industrial warehouse slabs scopes synced with other trades in Irving.

Proactive walk-throughs and photo documentation keep finish quality tight and cut rework.

Cylinder breaks, floor flatness, and inspection reports uploaded within 24 hours of each pour.

Experienced foremen guide every industrial warehouse slabs phase, protecting craftsmanship and safety culture.

Frequently asked questions

Industrial Warehouse Slabs in Irving, TX

Common questions from developers and property owners planning industrial warehouse slabs projects across North Texas.

What floor flatness do distribution centers require?

Modern distribution centers typically specify FF50/FL35 for conventional racking and FF70/FL50 or better for very narrow aisle (VNA) applications. The tolerance depends on your lift equipment and racking configuration—we work with your operations team to specify appropriate requirements.

How do you design joints for warehouse floors?

Joint design is critical for warehouse floor performance. We layout joints to minimize cuts through high-traffic areas, use armored joints at heavy-use locations, and specify joint spacing appropriate for slab thickness and reinforcement. Poor joint design is a leading cause of warehouse floor problems.

What slab thickness is typical for warehouse floors?

Industrial warehouses typically require 6-8 inch slabs depending on loads, with thickened areas at docks and under heavy equipment. We engineer thickness based on your actual loads rather than generic specifications—this often allows optimization while ensuring adequate capacity.

Do you coordinate with racking and equipment vendors?

Yes, we coordinate with racking vendors on anchor locations and load requirements, and with equipment suppliers on any special floor requirements. This coordination ensures the floor we build will work with your planned operations.

Ready when you are

Get a direct bid for your industrial warehouse slabs project

Developers and property owners: share your plans and we'll provide a complete project proposal with transparent pricing and single-source accountability as your general contractor.